C.D.S. Newsletter June 2012

Feature articles...

This issue focuses on underfloor air distribution (UFAD) and how it is implemented in TRACE™ 700. We address the following frequently asked questions:

- What is underfloor air distribution (UFAD)?

- How do stratification and underfloor plenum heat transfer affect space conditions?

- How is space stratification calculated in TRACE 700 with underfloor plenum heat transfer?

- How do I model UFAD systems in TRACE 700?

Also in this issue...

- Courses Available for LEED Credential Maintenance

- Frequently Asked Support Question

- Meet the C.D.S. Support Staff ... Rob Jordan and Mayra Reyes

What is underfloor air distribution (UFAD)?

Underfloor air distribution systems deliver conditioned air to the space through diffusers mounted in a raised floor.

Unlike traditional systems, in which complete mixing results in equally distributed temperatures, UFAD systems create a temperature gradient, with a cooler mixed-air region in the lower portion of the space and a higher temperature region in the upper portion (Figure 1). This stratification, along with the thermal performance of underfloor plenums, are key drivers in load calculations for UFAD systems.

The potential benefits of a UFAD system include improved thermal comfort due to local direct control of supply airflow and reduced ventilation rates because of higher zone air-distribution effectiveness due to stratification.

While in reality many conventional air distribution systems experience some stratification, in TRACE™ 700 overhead distribution systems are assumed to provide well-mixed spaces whereas UFAD systems result in stratified spaces. TRACE™ 700 has been able to run UFAD calculations since version 6.2 in December 2008.

Figure 1

How do stratification and underfloor plenum heat transfer affect space conditions?

Space stratification is a simple concept in which several layers of air at a range of heights have different temperatures. In the case of UFAD systems, temperature stratification in the conditioned space will result in higher temperatures at the ceiling (higher than the room thermostat set point), which will change the heat transfer dynamics in a room and between floors.

Figure 2 depicts a room air temperature profile that EnergyPlus uses in its room air model method UCSD UFAD Interior Underfloor Air Distribution. This model is also used as the basis for the TRACE™ 700 room air temperature profile for UFAD systems. This illustration is important as it determines the parameters for load calculations in the space.

Figure 2

Where:

The average occupied zone is from the ankle level (4”) to the head level (67”). In an ASHRAE Journal article on UFAD calculations, Bauman and Webster [1] state that the temperature difference calculated from the head to the ankle cannot exceed the limit of 5°F. This 5 degree maximum difference is defined as the acceptable comfort condition for standing occupants in a stratified room. Since the temperature differential is so low, UFAD systems provide supply air at higher temperatures when compared to overhead systems.

Furthermore, since the temperature can be drastically different at certain heights, the radiant contribution of the room loads can have a major effect on temperatures in the room and plenums. Including the radiative heat transfer from the ceiling to the floor and the conduction through the raised floor into the supply plenum, there will be a 35% to 45% heat gain into this supply underfloor plenum and a net heat loss from the return plenum of 10% to 15% [1].

To summarize the important factors for analyzing UFAD systems, as cool supply air passes through the underfloor plenum, it is exposed to heat gain from both the floor slab below and the raised floor above. This heat gain can be large and result in a temperature gain to the supply air inside the plenum. This will then lead to a possible increase in supply airflow to counter the heat gain.

______________________________________

[1] Bauman, F. and T. Webster. "Cooling Airflow Design Calculations for UFAD." ASHRAE Journal (October 2007).

How is space stratification calculated in TRACE 700 with underfloor plenum heat transfer?

The UFAD algorithm in TRACE 700 is derived from research by the Center for the Built Environment at the University of California as well as some methodology in the EnergyPlus program.

Please contact C.D.S. Support for more information about TRACE 700 UFAD calculations.

How do I model UFAD systems in TRACE 700?

For more information about UFAD systems, including how to model them in TRACE 700, refer to the TRACE 700 User's Manual (pp. 4-84 through 4-87). A PDF of the manual can be accessed from TRACE 700 by selecting Help > Documentation > User's Manual.

Courses Available for LEED Credential Maintenance

On-demand courses are available on the Trane.com Continuing Education offering, including courses that qualify for 1.5 LEED-specific continuing education (CE) hours from the U.S. Green Building Council (USGBC). As part of USGBC’s credential maintenance program, LEED APs are required to earn 30 CE hours biennially, 6 of which must be LEED-specific. View the course offerings at www.trane.com/continuingeducation.

Course Spotlight: High-Performance VAV Systems

This course will discuss design and control strategies that can significantly reduce energy use and ensure proper ventilation in VAV systems. Topics include ventilation system design and control, optimized VAV system controls, cold air distribution, and other energy‐saving strategies. [Runtime 75 minutes]

Frequently Asked Support Question

What does the return airflow represent in the Checksums reports?

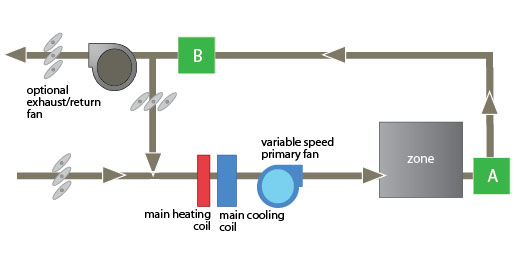

TRACE 700 defines return airflow as the volume of air returning from the conditioned space (not the portion of the airflow returned to the coil). The return airflow typically travels through a plenum or ductwork, although room direct configurations are also possible for certain system types. The volume of return airflow is used to size the return fan (if one is being modeled). A portion of the return air is typically exhausted out of the building through the system exhaust and the remaining volume is returned to mix with the outside air. If you want to determine the volume of return air that is mixing with the outside air, you simply subtract the exhaust air cfm from the return air cfm shown on the appropriate Checksums report.

Return airflow

The initial condition of the air leaving the room return grilles will equal the room condition. Therefore, the following will be true at point A in the return airflow:

- Return Air Dry Bulb = Design Room Dry Bulb

- Return Air Specific Humidity = Design Room Specific Humidity

TRACE calculates the return air temperature based on the selected return air path, calculated return airflow and the calculated loads to the plenum. Calculated plenum loads are based on user inputs. For example, assuming a plenum return, the following will be true at point B in the return airflow.

- Return Air Dry Bulb = [Plenum Airflow * Plenum Dry Bulb + Return Airflow Lighting Load + Return Airflow Misc. Load + Return Airflow Solar Load]/ Plenum Airflow

It is important to note that the use of corridor, ducted, or room direct returns will use different (but very similar) equations. Also, if a return fan is installed in the plenum, the return air temperature increase caused by the fan will need to be added to the Return Air Dry Bulb calculated at point B.

C.D.S. is growing ... software sales continue to grow as the focus on energy and cost savings becomes increasingly important. Our staff has nearly doubled in the last two years, giving us more manpower to provide world-class customer service, conduct training, and develop new features for our software.

We're excited about all the fresh and diverse new talent we have. Their experiences range from new graduates to seasoned HVAC professionals. When new marketing engineers start in C.D.S., they attend the Trane Graduate Training Program, an intense, 16-week course that covers HVAC fundamentals, systems, and products. When they return to C.D.S., they go through additional software and support training to better serve C.D.S. customers. Marketing engineers also conduct C.D.S. software training sessions.

To help you get to know us, we’ll be introducing our new staff members to you in this and upcoming C.D.S. newsletters.

ROB JORDAN

Rob Jordan joined C.D.S. as a marketing engineer in January 2011. After graduating with a civil engineering degree in 2007 from Colorado State University, Rob spent three years working for a boat manufacturer as a sales and design engineer. Originally from La Crosse, he spends the majority of his time enjoying the outdoors by biking, playing soccer and tennis, or water/snow skiing.

If you had to live in a TV show for a month, which show would it be and why?

I would live in Planet Earth so that I would be able to travel around to the most pristine locations on Earth. If you’re unfamiliar, the locations vary from the jungle to deserts to caves.

If you could invite any three people (living or dead) to a dinner party, who would it be and why?

- Yvon Chouinard – Has an amazing life story starting his company, Patagonia.

- Richard Branson – Incredible journey that he made to be who he is today, amazing stories.

- Jim Morrison – One of the most interesting personalities in recent history.

MAYRA REYES

Mayra joined C.D.S. as a marketing engineer in March 2011 after working for 3½ years in sales for the Trane office in Tijuana, Mexico.

She holds a Bachelor of Science degree in Mechatronics Engineering from the Monterrey Institute of Technology in Mexico City. Outside of work, Mayra enjoys traveling, art, reading, and crafting.

What is your most prized possession?

I love my freedom in every sense.

My favorite thing about working in C.D.S. is…

Interacting with our customers—I have always enjoyed helping others. When I was in sales, it was greatly satisfying to be able to help my customers find better solutions. In C.D.S. I can also help customers deal with their everyday work, brainstorming solutions for different situations.

Contributors: C.D.S. marketing engineers Kit Fransen, Ray Slaughter, Rob Jordan, and Mayra Reyes

C.D.S. Newsletter October 2012